We provide our customers with high-quality electronics original design manufacturing services with strict compliance with the deadlines at the most competitive overall price.

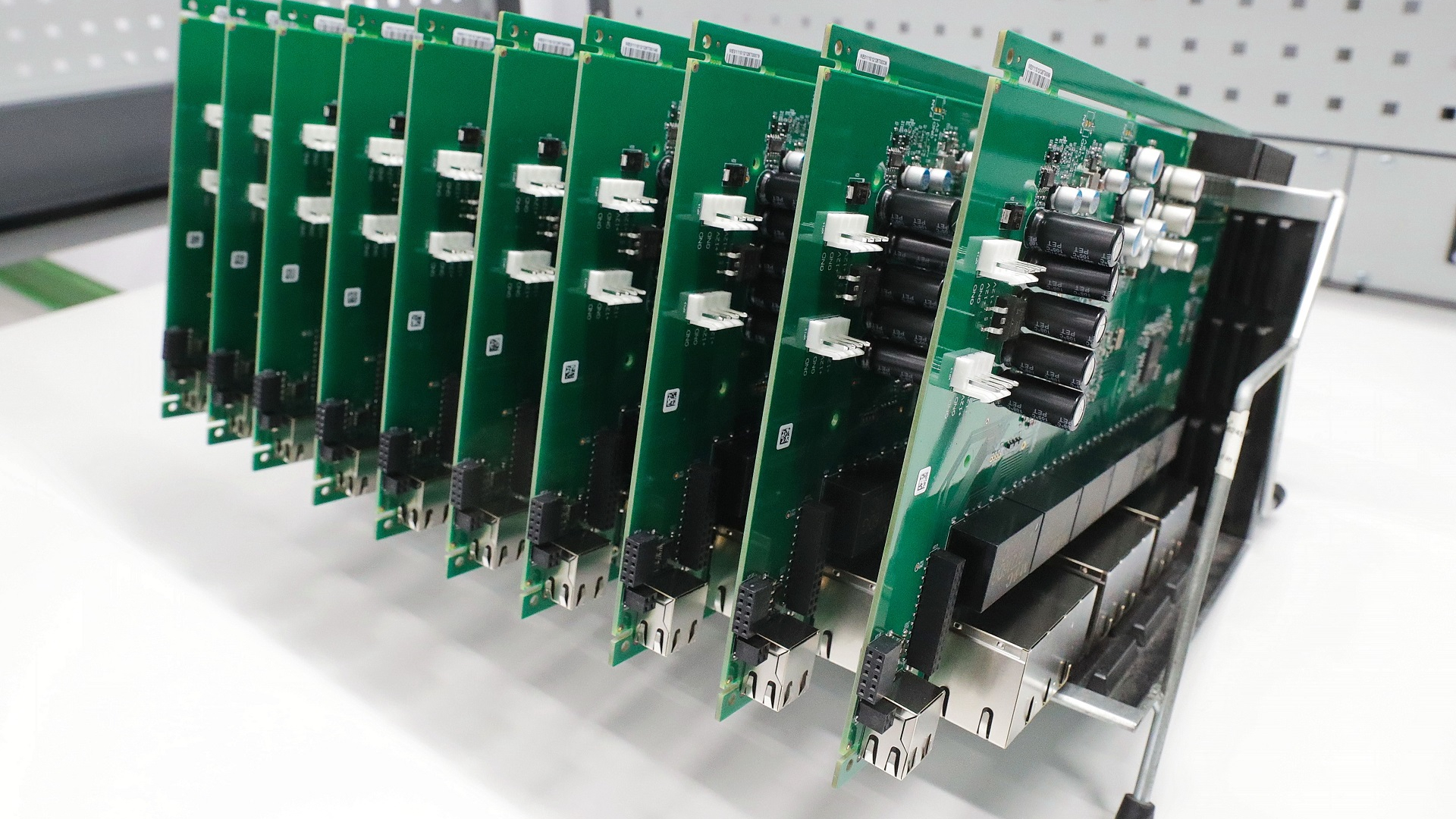

We have reliable and state-of-the-art manufacturing facilities and processes for the assembly of highly complex printed circuit boards, manufacture of electronic systems and modules, where quality and reliability play a key role.

-

2007

Under the Russian distributor of electronic components, Macro Group, an "original design manufacturing of electronics" subdivision was established.

-

2009

Purchase of an SMT assembly line, its siting in rented premises.

-

2015

Purchase of industrial territories with production buildings, installation of 2 of own SMT-assembly lines and organization of turnkey manufacturing of electronics on an area of 2,000 m2.

-

2020

Commencement of construction of a 4,000 m2 production building to expand the existing production facilities.

-

2021

Installation and launching of 4 state-of-the-art SMT-assembly lines in the new building.

Installation and launching of the wave soldering system GoWave of SEHO Systems with local nitrogen insertion of the solder waves. -

2022

Launch of ODM production. VayoPro-DFM Expert integration. Participation in national projects.

-

2023

Expansion of the equipment park.

-

2024

Implementation of production and manufacturing operations management system (MES/MOM)

-

2025

Start of construction of a new 10,000 m2 plant

-

2026

Future

| Establishment | 2007, as part of Macro Group Group of Companies |

| Location | St. Petersburg, Russia |

| Activities | Original design manufacturing of electronics |

| Employees | more than 150 |

| Manufacturing | 4,000 m2 |

Among the TOP-10 original design manufacturers of electronics in Russia.

| Line 1 | Line 2 | Line 3 | |

| Stenciled printer for application of solder paste | Panasonic SPG2 | Panasonic SPG2 | DEK Horizon 03Ix |

| Automated solder paste inspection (3D SPI) | KOH YOUNG KY8030-2 | KOH YOUNG KY8030-2 | KOH YOUNG KY8030-2 |

| Surface mount component fitter 1 | Panasonic NPM-W2 16/16 | Panasonic NPM-W2 16/16 | Mirae MR40LP |

| Surface mount component fitter 2 | Panasonic NPM-W2 16/16 | Panasonic NPM-W2 16/8 | Mirae MR40LP |

| Surface mount component fitter 3 | Panasonic NPM-W2 16/8 | Panasonic NPM-W2 8/3 | Mirae MR40LP |

| Surface mount component fitter 4 | Panasonic NPM-W2 8/3 | Panasonic NPM-W2 8/3 | Mirae MR40LP |

| Surface mount component fitter 5 | Panasonic NPM-W2 8/3 | ||

| Reflow conveyer furnace | REHM VXS air 4550 | SMT QP L Vacuum | ERSA HotFlow 2/12 |

| Automatic optical inspection of conveyer type | KOH YOUNG ZENITH | KOH YOUNG ZENITH | Pemtron Athena 8800PRO L |

Production capabilities of SMT assembly lines

- range of dimensions of components: from 01005 to 60 × 60 mm

- used types of enclosure: SOIC, PLCC, TSOP, QFP, BGA, flip-chip, surface-mounted connectors up to 100 mm long, holders for SIM cards and memory cards, parts up to 10–20 mm high

- installation of microcircuits with a lead pitch of 0.3 mm

- dimensions of the printed circuit board from 75 × 50 × 0.4 mm to 445 × 485 × 4.0 mm

- width of the technological field for gripping and fixing the board – 5 mm

- PCB thickness: 0.4 to 4.0 mm

- 100% automated quality control of solder paste application

- 100% automated quality control of soldering

- assembly of storage systems of 4 and 5 generations of 350+ PKI enclosure types

- Selective soldering unit ERSA VERSAFLOW 3/45

- Selective soldering unit ERSA Versaflow One

- Nitrogen wave soldering unit SEHO GoWave

- Nitrogen wave soldering unit ERSA Powerflow Ultra XL

- Automated Optical Inspection system Pemtron EAGLE 3D 8800 TWIN

- Automated Optical Inspection system Pemtron Athena 8800PRO L

- Press-Fit 677430-2

- Soldering stations Weller WD-1M, JBC CD-2BQF и JBC HDE-2D

- Repair station ERSA IR/PL650A

- Automatic cleaning system HyperSWASH

- Washing unit KED 600

- Laser marker Panasonic LPS-C

- X-ray control unit Nordson DAGE Quadra7

- X-ray control unit XSCAN-A130H